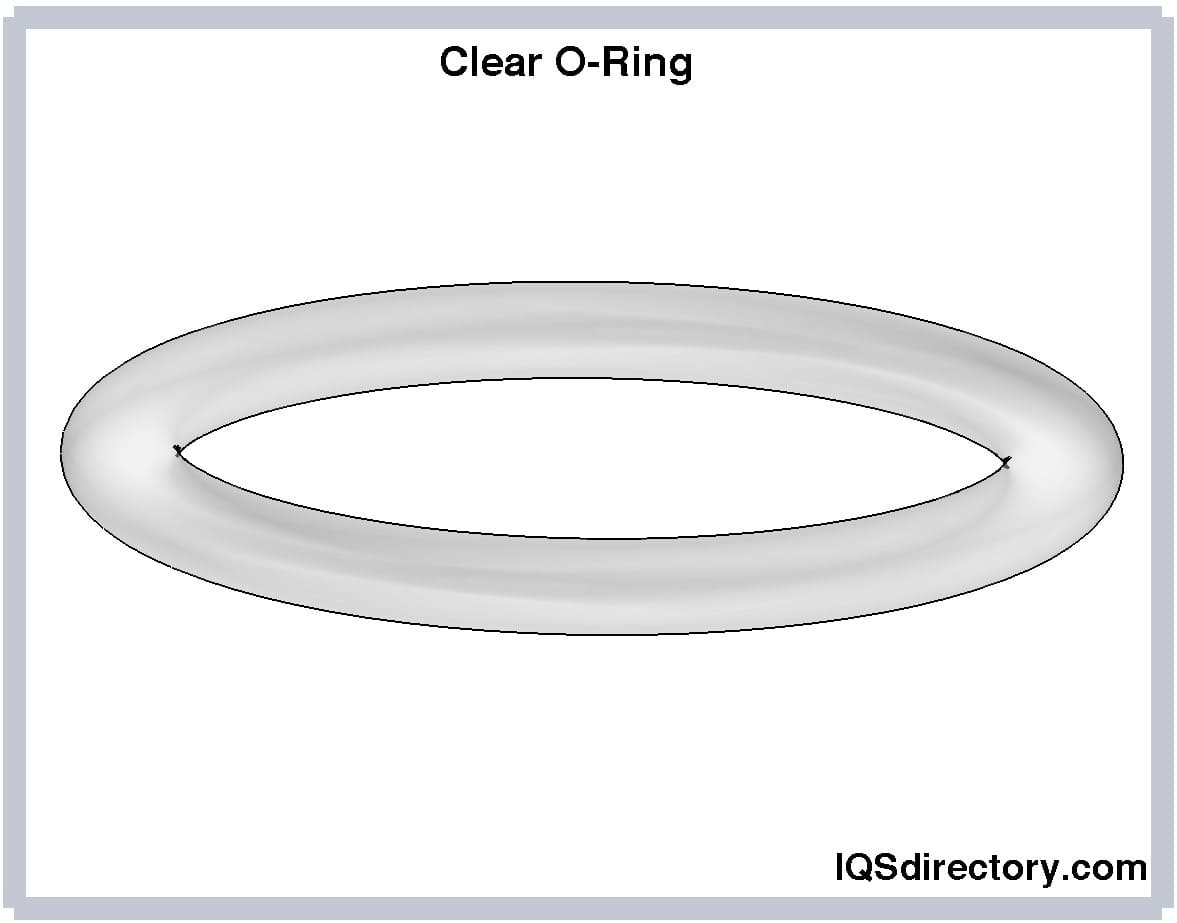

A clear O-ring is a flat, thin, doughnut-shaped elastic loop used as a seal for static and dynamic applications. Only a limited number of materials can give a transparent color, including silicone, Teflon, and polyurethane. However, these materials are not necessarily clear in their natural form, so additives must be applied. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Clear O-Ring Manufacturers

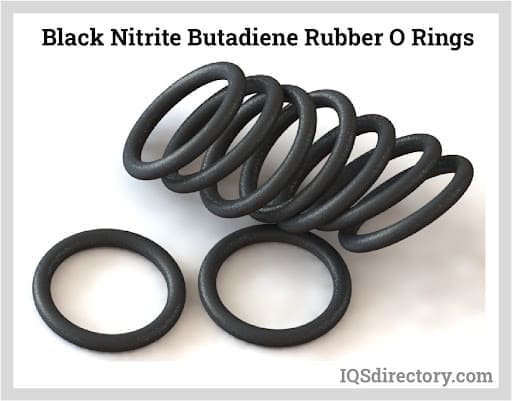

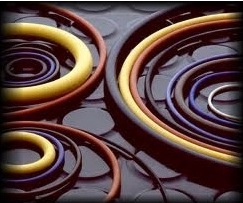

O-rings are essential mechanical components widely used as seals between structures such as pipes, tubes, pistons, and cylinders. Their primary purpose is to prevent the leakage of liquids or gases in static or dynamic applications. O-rings are available in a broad range of materials—including silicone, fluorocarbon (Viton), EPDM, nitrile (Buna-N), and more—each chosen for its unique properties tailored to specific industrial and commercial applications. Highly pliable and flexible, O-rings are engineered for chemical resistance, temperature stability, odorlessness, and long-term sealing performance, making them indispensable across multiple industries.

When O-rings are installed between two surfaces, they act as a barrier, effectively blocking the leakage of fluids or gases. In static sealing applications, O-rings remain stationary to maintain pressure or seal a vacuum, while in dynamic applications, they accommodate reciprocating or rotating motion. These self-energizing mechanisms allow O-rings to apply pressure within tubes, cylinders, or other enclosures, creating a robust and reliable seal. This versatility makes O-rings one of the most popular and cost-effective sealing solutions on the market.

How Clear O-Rings Are Manufactured

Clear O-rings, often made from materials such as silicone or polyurethane, are manufactured using advanced extrusion and molding techniques. The initial step involves the extrusion of elastomeric compounds, which are then precisely shaped for the subsequent molding process. This method ensures the consistent quality and dimensional accuracy necessary for critical sealing applications.

During extrusion, elastomer material is formed into continuous sheets or strands. These sheets are heated and forced through a die, which imparts the desired cross-sectional shape. After extrusion, the material undergoes one of three primary molding processes:

- Compression Molding: Ideal for high-volume production of non-standard or custom O-rings, compression molding involves placing pre-formed elastomer blanks into a heated mold cavity. Pressure is applied to shape the O-ring, ensuring uniform density and optimal sealing performance. This process is cost-effective for small runs and complex shapes.

- Injection Molding: Suited for large-scale production of standard O-rings, injection molding involves injecting liquid elastomer into a closed mold. This process allows for rapid cycle times, high precision, and minimal material waste, making it ideal for producing consistent, high-quality seals in bulk.

- Transfer Molding: A hybrid of compression and injection molding, transfer molding introduces the elastomer into a closed mold via a transfer chamber. This method minimizes flash and provides tighter dimensional tolerances, making it suitable for O-rings requiring exact specifications and reduced environmental impact.

The choice of manufacturing process is determined by factors such as production volume, material selection, and the required dimensional tolerances. For specialized applications—such as in food processing, pharmaceuticals, or medical devices—clear O-rings are often produced from FDA-compliant silicone to ensure purity, transparency, and safety.

Types of Clear O-Rings: Static vs. Dynamic Seals

O-rings are categorized not only by the materials used in their production but also by their functional design. The two principal categories are static and dynamic O-rings, each tailored to specific operational requirements.

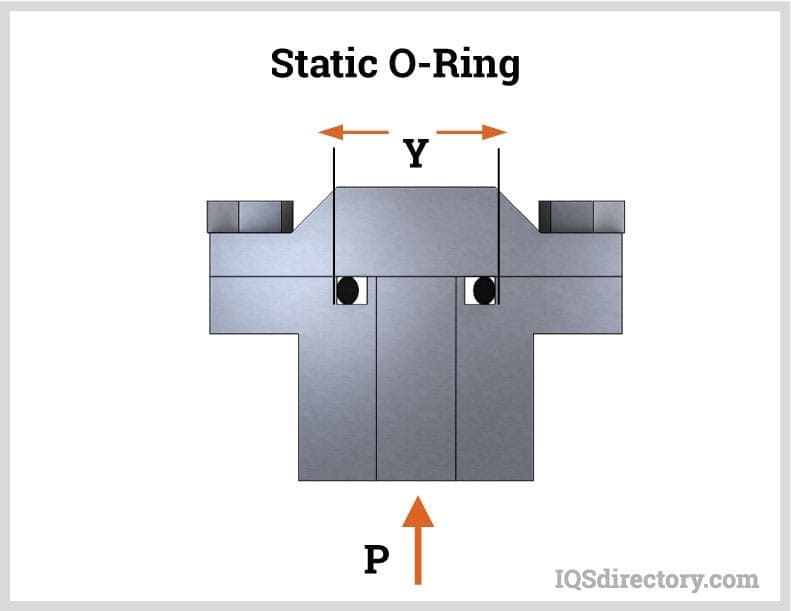

Static O-Ring Seals

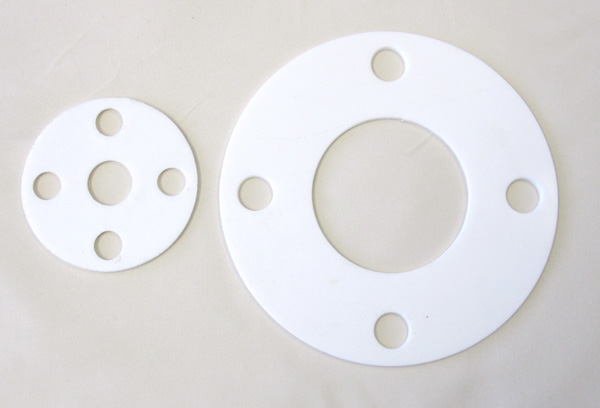

Static O-rings are designed to seal two or more surfaces that remain stationary relative to each other. In these applications, the O-ring is compressed between mating surfaces—usually in a groove or cavity—to create an effective seal. The sealing action typically occurs on the face or radial surface of the ring.

Common examples of static sealing applications include:

- Pipe flange seals

- Hydraulic cylinder end caps

- Valve covers and manifold connections

- Vacuum chambers and enclosures

To achieve optimal sealing, a groove is precision-cut into one surface, and the O-ring—sized for exact fit—is installed in the groove. A second surface is then mated, compressing the O-ring and forming a leak-proof static seal. Because there is no relative movement, static O-rings generally experience less wear and have a longer service life compared to dynamic seals.

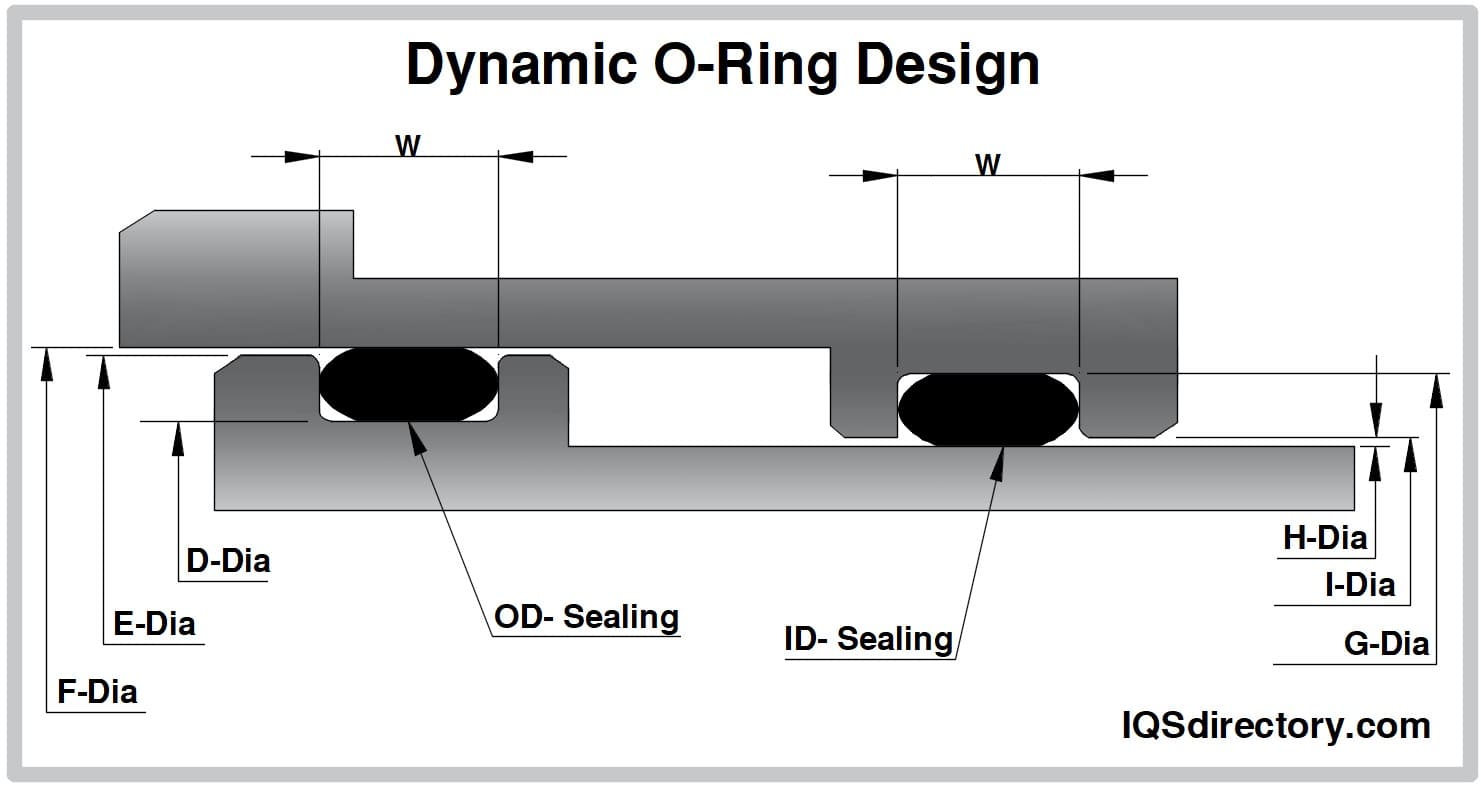

Dynamic O-Ring Seals

Dynamic O-rings are engineered to seal between components that move relative to one another. These seals must withstand constant friction, pressure changes, and abrasive forces, making material selection and proper lubrication critical for performance and longevity.

Dynamic O-ring applications include:

- Hydraulic and pneumatic cylinder rods

- Piston seals in pumps and actuators

- Rotary shaft seals in motors and gearboxes

- Oscillating mechanisms and mechanical linkages

Because dynamic O-rings are subject to continuous motion, they tend to wear out faster than static seals. To mitigate this, they are often manufactured from abrasion-resistant materials and require regular lubrication to reduce friction and prevent premature failure. The two most common types of dynamic O-ring seals are:

- Reciprocating Seals: Used in applications where a rod or piston moves back and forth. These O-rings must maintain a tight seal under repeated motion and fluctuating pressure.

- Rotary Seals: Used to seal a shaft that rotates within a housing. The O-ring must provide a reliable seal while accommodating rotational velocity and potential misalignment.

For both reciprocating and rotary applications, the surface finish of the mating parts is crucial. A finish that is too smooth may not retain lubricants, while a rough finish can accelerate wear. Selecting the right dynamic O-ring involves considering material hardness, chemical compatibility, pressure ratings, and operating temperatures.

Applications and Uses of Clear O-Rings

Clear O-rings—most commonly produced from high-purity silicone or polyurethane—are preferred in industries where visibility, cleanliness, and non-contaminating properties are paramount. They offer unique advantages in applications requiring transparency, chemical resistance, and compliance with regulatory standards.

Common applications and use cases for clear O-rings include:

- Food and Beverage Processing: Clear silicone O-rings are FDA- and NSF-compliant, making them ideal for sealing equipment in food and beverage manufacturing where contamination must be prevented and visual inspection is critical.

- Pharmaceutical and Medical Devices: Used in pumps, valves, syringes, and diagnostic equipment, clear O-rings ensure a sterile environment and allow for easy detection of foreign particles or wear.

- Electronics and Semiconductor Manufacturing: Their chemical inertness and non-marking properties make clear O-rings suitable for cleanroom environments, wafer processing, and sensitive instrumentation.

- Transportation and Aerospace: O-rings are essential for leak prevention in braking systems, fuel lines, engine components, and hydraulic assemblies. Their ability to withstand extreme temperatures and pressure changes is vital for aircraft safety and reliability.

- Dental and Orthodontic Implants: Clear O-rings are commonly used in dental applications, such as securing implant abutments and providing cushioning for removable prosthetics.

- Cosmetics and Personal Care Packaging: Used to seal bottles, pumps, and dispensers, ensuring product integrity and preventing leaks.

Want to learn more about the best O-ring materials for your industry? Explore our O-Rings Resource Library for in-depth guides on chemical compatibility, temperature ratings, and regulatory compliance.

Key Benefits of Using Clear O-Rings

Choosing clear O-rings for your sealing applications offers a range of unique advantages, including:

- Visual Inspection: Transparency allows operators and maintenance personnel to monitor for contamination, wear, or failure without dismantling equipment.

- Chemical Resistance: Silicone and polyurethane clear O-rings offer excellent resistance to a broad spectrum of chemicals, solvents, and cleaning agents.

- High Purity: Manufactured from FDA- and USP Class VI-compliant elastomers, clear O-rings are suitable for hygienic and sterile environments.

- Temperature Flexibility: Capable of withstanding extreme temperatures—from cryogenic conditions to high-heat environments—without losing sealing integrity.

- Non-Toxic and Non-Staining: Ideal for medical, food, and cosmetic applications where product purity and aesthetics are essential.

- Customizability: Available in a range of sizes, cross-sections, and hardness ratings to suit any application or regulatory requirement.

Considering a switch to clear O-rings? Request a sample or consult with our material experts to determine the best fit for your specific sealing needs.

How to Select the Right Clear O-Ring for Your Application

The selection of an appropriate O-ring is a critical decision that impacts equipment reliability, safety, and operational efficiency. Here are key decision factors to consider when evaluating clear O-ring options:

- Material Compatibility: Ensure the O-ring material is resistant to the chemicals, fluids, or gases present in your application.

- Temperature Range: Verify that the elastomer can handle the minimum and maximum temperatures in your operating environment.

- Pressure Ratings: Assess the maximum pressure the seal must withstand, factoring in static or dynamic loads.

- Size and Tolerances: Choose an O-ring with precise dimensions and tolerances for a secure, long-lasting seal.

- Regulatory Compliance: For food, beverage, or pharmaceutical use, ensure the O-ring meets all necessary FDA, USP, or NSF certifications.

- Environmental Factors: Consider UV exposure, ozone, and potential for abrasion or mechanical stress.

Have questions about sizing, installation, or material performance? Ask our O-ring specialists for personalized recommendations and technical support.

Choosing the Right Clear O-Ring Supplier

Selecting a reliable clear O-ring supplier is vital for ensuring consistent quality, timely delivery, and expert technical support. Here are steps to guide your supplier evaluation process:

- Review Experience and Capabilities: Use our comprehensive directory of clear O-ring suppliers to compare companies, manufacturing capabilities, and industry certifications.

- Assess Product Range: Look for suppliers offering a wide selection of standard and custom O-ring sizes, materials, and hardness levels to suit your unique requirements.

- Evaluate Quality Assurance: Confirm that your supplier follows strict quality control protocols, such as ISO 9001 certification and batch traceability.

- Request Technical Support: Top suppliers provide engineering support, application testing, and prototype development to ensure optimal sealing performance.

- Compare Pricing and Lead Times: Use our patented website previewer and RFQ form to quickly obtain quotes from multiple suppliers, streamlining your sourcing process.

To ensure you have the most constructive outcome when purchasing clear O-rings, compare several companies using our directory of clear O-ring suppliers. Each clear O-ring supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each clear O-ring business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple clear O-ring companies with the same form.

Frequently Asked Questions About Clear O-Rings

- What are the most common materials for clear O-rings?

High-purity silicone and polyurethane are the leading choices for clear O-rings due to their transparency, flexibility, and chemical resistance. Some specialty applications may use fluorosilicone or TPE materials for enhanced performance. - Are clear O-rings suitable for high-temperature environments?

Yes, silicone-based clear O-rings can typically withstand continuous exposure to temperatures ranging from -60°C to 230°C (-76°F to 446°F), making them suitable for many demanding industrial settings. - Can clear O-rings be used in food and beverage equipment?

Absolutely. FDA- and NSF-compliant silicone O-rings are ideal for food processing, packaging, and beverage dispensing systems where purity and visual inspection are important. - How do I determine the correct size O-ring for my application?

Use an O-ring sizing chart or consult with your supplier. Accurate measurement of groove dimensions and application conditions is critical for optimal sealing. - What causes O-ring failure and how can it be prevented?

Common causes include improper installation, chemical incompatibility, excessive pressure, or inadequate lubrication in dynamic applications. Prevent failure by selecting the right material, ensuring correct installation, and performing regular maintenance.

Related Resources

Conclusion: Optimize Your Sealing Solutions with Clear O-Rings

Clear O-rings offer a unique combination of visual accessibility, chemical resistance, and regulatory compliance, making them the preferred choice for a wide range of industries including food processing, medical devices, aerospace, and electronics. By understanding the types, applications, and selection criteria for O-rings, you can enhance equipment reliability, minimize downtime, and ensure safety in critical operations.

Whether you need standard or custom clear O-rings, choosing the right material and supplier is key. Take advantage of our supplier directory, technical resources, and expert support to make informed decisions that support your business goals.

Ready to enhance your sealing systems? Contact us for a quote or technical consultation today and discover why clear O-rings are the industry standard for transparent, high-performance sealing solutions.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services