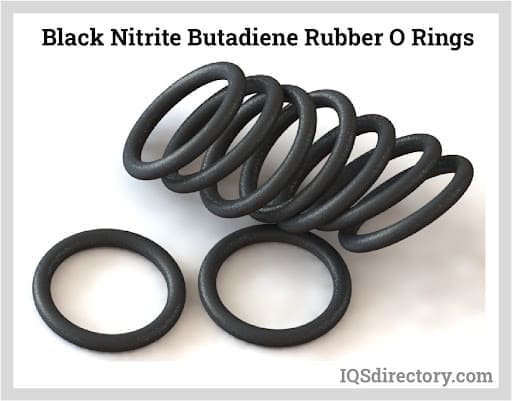

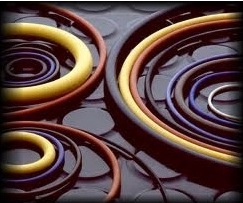

In contrast to O-rings, which are perfectly round shapes called toruses, flat O-rings are round shapes with flat sides called toroids. Flat O-rings perform similarly to O-rings in that they are used for gasket and high-pressure sealing applications. However, some spaces are unsuitable for sealing with round O-rings. The way flat O-rings are made is intended to seal areas with similar shapes effectively. Square or lathe-cut rings are other names for flat O-rings. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Flat O-Ring Manufacturers

Flat O-Rings: Comprehensive Guide to Manufacturing, Applications, and Benefits

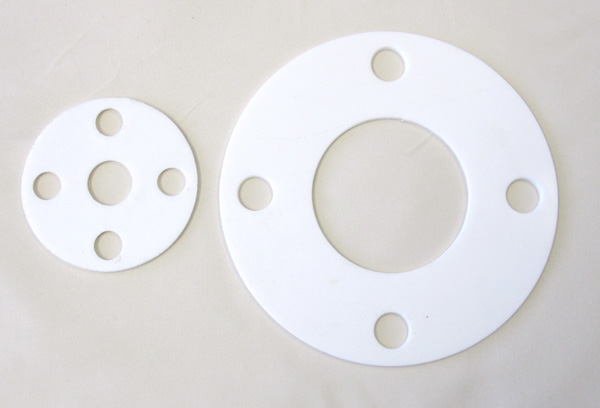

Flat O-rings are essential sealing components used across a broad range of industries, from automotive and aerospace to industrial equipment and consumer products. Unlike standard round O-rings, flat O-rings feature a square or rectangular cross-section, offering unique sealing characteristics and performance advantages. This in-depth guide explores the manufacturing process, typical applications, benefits, material options, and key considerations for selecting the right flat O-ring for your needs. Whether you are sourcing flat O-rings for OEM production, maintenance, or specialized sealing solutions, understanding these elements will help you make informed decisions and achieve optimal results.

Manufacturing Process of Flat O-Rings

Flat O-rings with square or rectangular cross-sections are manufactured using specialized processes to ensure precision and durability. The primary method involves cutting O-rings from extruded tubes or extruding them from molds that have a square or rectangular cavity. This process, often referred to as die cutting, uses machines equipped with specifically shaped blades to achieve accurate dimensions and high repeatability for every product. After extrusion, flat O-rings undergo curing procedures, which include trimming or knife cutting to refine their shape and remove excess material for a perfect fit.

To optimize the chemical and physical properties of the finished flat O-rings, various additives and compounding agents are mixed into the raw material—such as silicone, Viton, Nitrile (Buna-N), EPDM, or Teflon—while it is still in a molten state. These additives can improve resistance to high temperatures, chemicals, abrasion, and other environmental factors, making the O-rings suitable for demanding industrial and commercial sealing applications.

Modern flat O-ring manufacturing may also involve secondary operations such as laser cutting, precision CNC trimming, and automated inspection to ensure the highest quality standards. Manufacturers often perform rigorous quality control checks, including dimensional analysis, tensile strength testing, and compression set measurement to ensure each flat O-ring meets or exceeds industry standards like ASTM D2000 or ISO 3601.

Common Materials Used in Flat O-Ring Production

- Silicone (VMQ): Known for excellent flexibility, wide temperature range (-60°C to +230°C), and resistance to UV, ozone, and weathering. Ideal for food, medical, and outdoor applications.

- Viton (FKM): Offers high resistance to chemicals, fuels, and high temperatures (up to 250°C). Commonly used in automotive, aerospace, and chemical processing industries.

- Nitrile Rubber (Buna-N): Cost-effective and resistant to oils, fuels, and greases. Widely used in automotive and industrial hydraulic systems.

- EPDM: Excellent resistance to steam, water, and weathering. Preferred for HVAC systems, plumbing, and outdoor applications.

- PTFE (Teflon): Outstanding chemical resistance, low friction, and high-temperature performance. Used in chemical processing, pharmaceutical, and food processing industries.

Are you looking for custom flat O-ring materials or specialized sealing solutions? Contact a flat O-ring specialist to discuss your requirements and receive expert guidance on the best material options for your application.

Applications of Flat O-Rings

O-rings are among the most adaptable sealing components in modern engineering, offering reliable performance in diverse settings. Flat O-rings, in particular, are chosen when a robust, low-profile seal is required or when traditional round O-rings may not provide adequate coverage. Here are some of the most common and critical applications for flat O-rings:

Fishing

Flat O-rings are employed in a variety of industries, including fishing, where they are used to stabilize bait. Instead of using the bait as the hook, the O-ring is slipped around the bait and hooked. Live bait is kept alive and more likely to draw fish if an O-ring holds it. Depending on the size of the ring, they can hold live bugs, live worms, or chunks of meat. Furthermore, using a flat O-ring lessens the possibility of the fish hooking the bait and slipping off the hook. This strategy has advantages for fishermen because it reduces the frequency of bait replacement.

Ring producers advise using flexible rings composed of rubber or flexible plastic for fishing applications. Flat O-rings that lack flexibility are more prone to break during fishing. Because they are non-toxic and won't pollute the fish's body with toxins, polyurethane, latex rubber, and silicone are excellent materials for fishing applications. Some manufacturing businesses produce O-rings specifically for fishing because flat O-rings can be useful in this industry.

Transportation

Flat O-rings are essential for sealing the various fluids that are a component of the systems in buses, trucks, and automobiles. The various fluids included in automobiles include fuels, refrigerants, and lubricating oils, each of which has a particular operating temperature and rate of consumption. They serve as a sealant and leak prevention measure for braking systems, engine lubrication, and transmission fluids. In heavy-duty vehicles and commercial fleets, flat O-rings are also used in diesel engines, power steering systems, and hydraulic brakes where reliability and long-term durability are crucial.

Aerospace

Flat O-rings play a crucial role in the design of airplanes because they shield jet engines from dangerous circumstances and large temperature swings. Each of the thousands of O-rings used in commercial aircraft is created to carry out a specific task, such as adjusting to extreme pressure variations, harsh lubricants and fluids, and abrupt temperature changes. To fulfill the rising need of the new conditions, new flat O-ring compositions must be developed due to changes in aircraft design. O-rings can now withstand operating temperatures of above 275 °F (135 °C) thanks to modern designs and improved compounds.

Flat O-rings are also widely used in spacecraft, drones, and military aircraft to provide critical seals in hydraulic systems, fuel lines, and avionics enclosures. Their ability to maintain sealing integrity under severe vibration and high-altitude pressure fluctuations makes them a preferred choice in aerospace engineering.

Industrial Equipment and Machinery

Flat O-rings are indispensable in a variety of industrial applications such as pumps, compressors, hydraulic presses, and pneumatic actuators. Their low profile and increased surface contact area enable superior sealing in flanges, valve covers, and cylinder heads. Flat O-rings are often specified for static sealing applications where precise alignment and leak prevention are critical.

Consumer Electronics and Appliances

In consumer products, flat O-rings are found in water filtration systems, coffee machines, blenders, and other appliances requiring watertight and dustproof seals. They are favored for their ease of installation, minimal maintenance needs, and compatibility with a wide range of housing materials.

Medical and Food Processing Equipment

Flat O-rings made from FDA-compliant materials, such as medical-grade silicone or PTFE, are used in medical devices and food processing machinery. They ensure sterile, leak-free operation in pumps, tubing connectors, and diagnostic equipment, where hygiene and contamination resistance are non-negotiable.

Which Flat O-Ring Is Right for Your Application?

Not sure which flat O-ring material or design best fits your use case? Ask an O-ring expert for personalized recommendations based on your operating environment, pressure ratings, and regulatory requirements.

Benefits of Flat O-Rings

Flat O-rings are sandwiched between two machine body components and act as a sealing mechanism during construction. However, flat o-rings do not require as much pressure or squeezing to function as their other o-ring cousins do. Therefore, when it comes time to replace them, they are simple to remove, considerably reducing maintenance downtime. Additionally, they require less friction, which results in less wear and tear and does away with the need for lubrication.

Flat O-rings benefit from these qualities by lasting much longer and being less expensive, especially in applications where abrasion is a major problem. Because they have corners, flat O-rings can be used in addition to round O-rings to seal off spaces where the former cannot. For instance, as flat O-rings have a bigger surface area and offer better coverage when screwed, they can be employed as a seal between an automobile's oil filter and oil housing. For most other applications, flat and round O-rings can be utilized interchangeably, except for certain situations.

Key Advantages of Flat O-Rings

- Enhanced Sealing Coverage: The flat profile ensures a larger surface contact area, reducing the risk of leaks in static and dynamic applications.

- Lower Compression Set: Flat O-rings are less likely to permanently deform under load, making them suitable for repeated use and long-term installations.

- Reduced Installation Force: Easier to install and remove, saving maintenance time and minimizing the risk of component damage.

- Versatility: Compatible with a wide range of fluids, gases, and operating conditions, especially when manufactured from specialty materials.

- Cost-Effectiveness: Longer service life and reduced need for lubrication or replacement make flat O-rings a budget-friendly sealing solution.

Comparing Flat O-Rings vs. Round O-Rings

When should you choose a flat O-ring over a round (standard) O-ring? Flat O-rings excel in applications where a broader sealing surface is needed or where space constraints exist. They also provide superior sealing in rectangular grooves or surfaces with minimal compression. Conversely, round O-rings may be preferred in dynamic or rotary applications due to their ability to roll and adapt to motion. Evaluating your specific sealing environment, pressure requirements, and mechanical constraints will help you select the optimal O-ring profile.

Typical Use Cases for Flat O-Rings

- Static seals in piping flanges and valve covers

- Seals for hydraulic and pneumatic cylinders

- Gaskets for electronic enclosures and connectors

- Seals for automotive oil and fuel filters

- Sealing applications in food processing and medical devices

Design and Customization of Flat O-Rings

Thermoplastic polymers and elastomeric rubbers, including silicone, Viton, and Teflon, create flat O-rings. In comparison to standard O-rings, flat O-rings' four-lobed design doubles their sealing surface. Additionally, they feature a smooth surface texture, thermal conductivity, tensile strength, a wide temperature range, and the capacity to seal under high pressures. However, they need to go through a different step in the fabrication process than other kinds of O-rings, which only go through molding. As a result, flat O-rings are harder to find than other types.

Customization Options

- Dimension Customization: Tailored inner and outer diameters, thickness, and cross-sectional shape to fit unique groove geometries.

- Material Selection: Choose from an array of high-performance elastomers for chemical resistance, temperature stability, or FDA compliance.

- Color Coding: Colored flat O-rings for easy identification in assembly lines or maintenance operations.

- Specialized Coatings: PTFE or other coatings for reduced friction, enhanced durability, or improved chemical compatibility.

- Bulk Packaging and Kitting: Custom packaging solutions for OEMs, distributors, and maintenance teams.

Decision Factors When Selecting Flat O-Rings

Choosing the right flat O-ring involves assessing multiple technical and operational criteria. Here are key decision factors for buyers, engineers, and maintenance professionals:

- Operating Temperature: Ensure the selected material can withstand minimum and maximum temperature extremes in your environment.

- Chemical Compatibility: Match the O-ring compound to the fluids, lubricants, or gases in contact with the seal.

- Pressure Rating: Consider the maximum and sustained pressures the O-ring must endure without extruding or failing.

- Installation Constraints: Check for available space, groove depth, and ease of access during installation or replacement.

- Certifications & Standards: For regulated industries, ensure O-rings meet FDA, USP Class VI, or other relevant certifications.

- Longevity and Maintenance: Balance initial cost with expected service life and ease of maintenance to minimize total ownership cost.

Choosing the Right Flat O-Ring Manufacturer

To ensure the most positive outcome when purchasing flat O-rings from a flat O-ring manufacturer, it is important to compare several companies using our directory of flat O-ring manufacturers. Each flat O-ring manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each flat O-ring business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple flat O-ring companies with the same form.

How to Select a Reliable Flat O-Ring Supplier

- Evaluate supplier track record in your industry (automotive, aerospace, medical, etc.)

- Check for ISO 9001 or other quality certifications

- Request sample O-rings for approval and testing

- Ask about custom manufacturing capabilities and minimum order quantities

- Compare lead times, pricing, and after-sales support

FAQs about Flat O-Rings

What is the difference between a flat O-ring and a gasket?

While both flat O-rings and gaskets are designed to create seals and prevent leaks, an O-ring is typically a molded or extruded ring, whereas a gasket is usually a flat, cut shape designed to fit between two surfaces. Flat O-rings combine the benefits of both by providing a ring-shaped seal with a flat profile, offering improved coverage and ease of installation in certain applications.

Can flat O-rings replace standard round O-rings?

Flat O-rings can often be used interchangeably with round O-rings in static applications, especially where a larger sealing surface is needed. However, for dynamic or rotary seals, round O-rings may provide better performance due to their ability to roll and adapt to movement. Always consult your application’s requirements before substituting one type for another.

Are flat O-rings suitable for high-pressure environments?

Yes, many flat O-rings are designed for high-pressure sealing, especially when made from advanced materials like Viton or PTFE and installed in properly engineered grooves. For extreme pressures, consult with an O-ring manufacturer to ensure the material and design meet your needs.

What industries rely most on flat O-rings?

Automotive, aerospace, industrial machinery, food and beverage processing, medical device manufacturing, and electronics are among the top industries utilizing flat O-rings for critical sealing applications.

How do I specify a custom flat O-ring?

Provide your supplier with precise dimensions (inner diameter, outer diameter, and thickness), material preferences, and any special requirements such as color, durometer (hardness), or certifications. For complex requirements, CAD drawings or sample parts can help ensure an exact match.

Get Expert Help with Flat O-Rings

Need assistance selecting the right flat O-ring for your project or application? Whether you’re seeking standard or custom O-rings, our technical team can help you evaluate options, compare materials, and ensure compliance with relevant standards. Contact us today for personalized support, technical datasheets, and fast quotes.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services