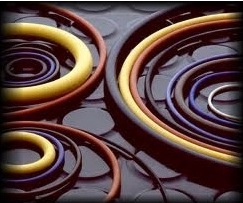

While elastomers continue to be a common choice for o-ring production, metals offer better temperature, pressure and corrosion resistant capabilities. These essential properties and others allow the use of this particular type of o-ring in aerospace, nuclear, power generation, semiconductor, oil and gas industries. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Metal O-Ring Manufacturers

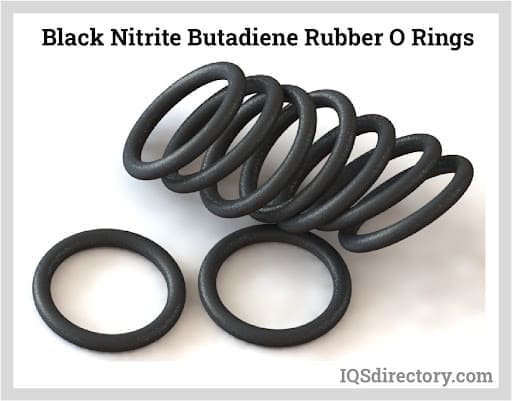

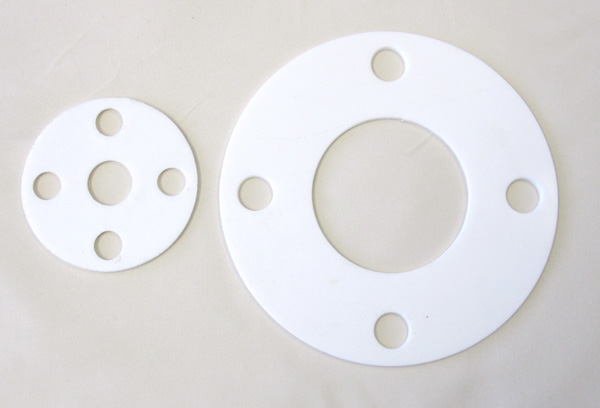

Metal o-rings are discs that are placed in piping, tubing, valves, vacuums and the like to create an impermeable seal within a joint, thereby blocking the passage of gases or liquids. Metal may be used in dynamic joints, though it is best suited to static compression.

When in place, the o-ring creates a four point seal unique to metal rings. Metal rings may also have plastic jackets, which abandon the four point seal in favor of the full contact of an elastomer product. Compression deformation causes the rubberized coating to spread and fill any cracks and gaps that might be found in the surrounding materials.

Just as metal o-rings sometimes utilize plastic attributes, metals such as carbon are used as fillers for elastomer compounds to prevent electrical arcing and static sparks.

There are three basic types of metal o-ring seals. Plain, self-energized and pressure-filled o-rings are all formed using die casting methods. Aluminum, nickel, silver, copper, steel alloys, inconel and gold are common materials utilized in the production of o-rings. There are also plastic based o-rings on the market, commonly cut from synthetic rubbers like viton and silicone.

Additionally, Teflon, cadmium, copper, nickel, silver, gold and indium may be used to plate or coat rings to increase corrosion resistance, fit and strength. Metal o-rings can also be heat-treated, age-hardened or annealed. The finishing requirements are determined by the specific use of an o-ring and the materials it will contain.

Heavy liquids, for example, do not generally require coating. Volatile fluids and gases such as helium or hydrogen, however, should be handled with extreme caution. Coating an o-ring containing volatile fluids will not only improve the quality of the seal, but act as a safety measure as well.

When selecting a base material or top coating, a buyer must also consider the temperature requirements of an application, since the useful temperature range of metal o-rings varies from -450°F to over 1300°F. No matter the material, o-rings play an integral role in the safe operation of many machines and must therefore be subject to rigid visual and dimensional inspection. Material, finish, temperature range, pressure range, vacuum range and diameter should all be carefully considered in the selection of a metal o-ring.

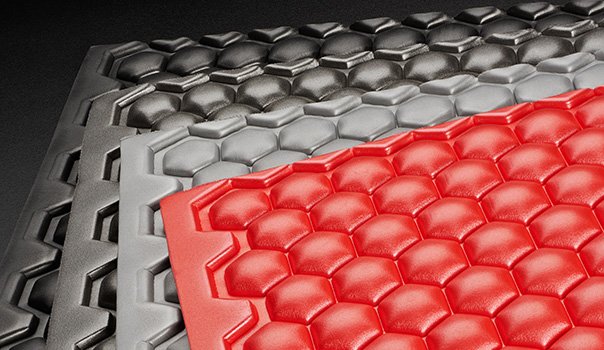

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services