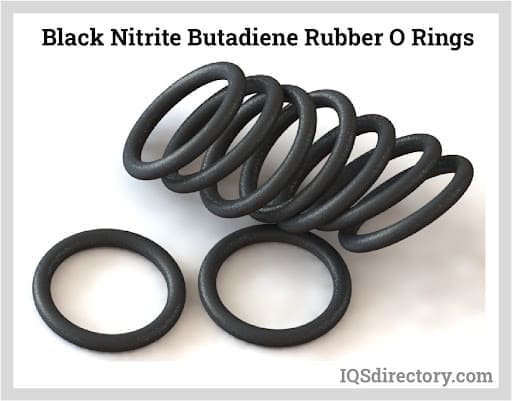

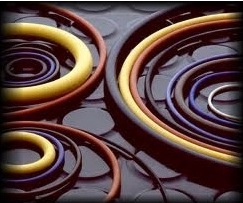

Nitrile is an elastomer that is known for its good stability against thermal aging, low resistance to friction and high chemical corrosion resistance. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Nitrile O-Ring Manufacturers

These properties and others allow the use of this particular type of o-ring in aerospace, automotive, oil field exploration and processing, petro-chemical, water processing, paper mills and other performance-demanding industries.

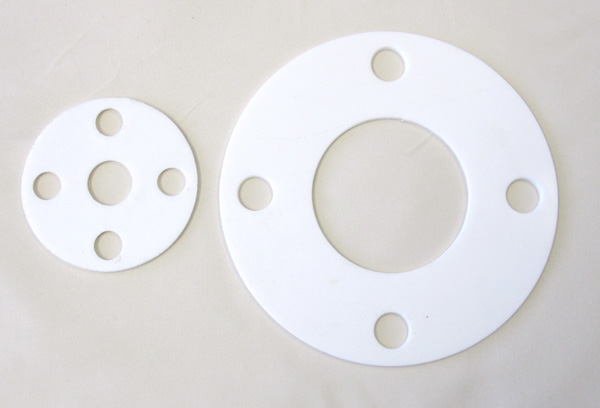

Nitrile O-rings are rubber o-rings that are placed between two parts connecting a machine or piping system to create an impermeable seal and block the leakage of gases or liquids. The disc is placed within a groove between two joint components. When pressure is applied to close the joint, the rubber material deforms.

This is known as compression deformation and is an integral feature of o-ring seals, as it completely closes any and all gaps between surfaces and objects. Compression may be continuous as it is with static seals, or interrupted with the motion of pistons or hydraulic cylinders as with dynamic seals.

Although low resistance to friction is a favorable characteristic of nitrile, lubricants are still used with this type of o-ring, to prevent wear and prolong the life of the product. Industries that favor nitrile o-rings include oil and gas companies, food and beverage companies, aerospace companies and chemical companies. Nitrile o-rings are versatile, partly because of the wide range of temperatures they can endure.

A synthetic latex, nitrile contains no latex proteins and has excellent resistance to wear and puncture. This particular elastomer has a higher degree of flexibility and solvent resistance than many alternative o-ring options. Additionally, the physical strength and retention of properties through prolonged chemical exposure make nitrile an excellent option for o-ring construction.

As nitrile compounds can withstand temperatures ranging from -40°C to 165°C, it is very versatile for both hot and cold applications. While nitrile rubber may be used independently, it is often saturated or hydrogenated in solutions of precious metal catalysts, which convert the natural double bonds of nitrile to more stable single bonds.

The degree of saturation can range from 4% to 10%. Hydrogenated nitrile butadiene rubber, carboxylated nitrile and highly saturated nitrile are just a few of the processed nitrile variations used to make o-rings. The fillers used exacerbate the already desirable qualities of nitrile and improve tensile strength.

The o-ring is created from these materials using several different rubber molding processes such as injection molding. When selecting the proper nitrile o-ring considerations should include width, thickness, inside diameter, outside diameter, intended use and the specific hydrogenated or saturated variation of the substance.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services