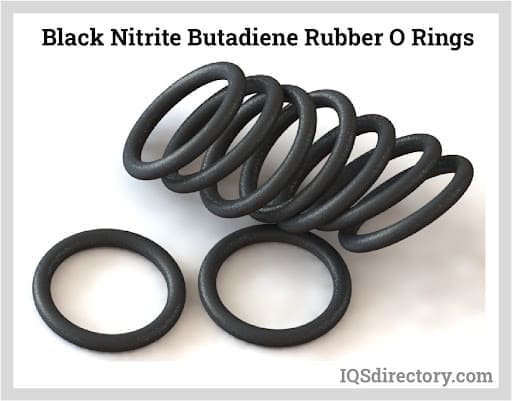

O-rings are disc or donut-shaped gaskets which can be used in dynamic or static applications. They are also referred to as packing joints. The seal compresses between the two machinery components and prevents the loss of fluid or gas. The rings are easily manufactured, relatively cheap, and dependable, making them the most common seals used in machinery worldwide.

Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More O-Ring Seal Manufacturers

How O-Ring Seals Function

O-rings seal through a mechanical deformation that creates a barrier through which a fluid may leak. They are inserted into a groove between two surfaces or molded to one surface to be sealed.

The rings are made of rubber, letting them compensate for any dimensional variations in the mating parts. When tightly secured, the seals form a water and airtight barrier, which blocks leakages and escaping of contents from in between the joined parts.

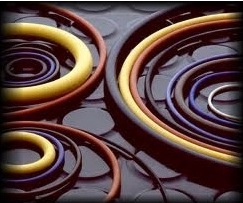

Types of O-Ring Seals

O-rings are a common part of many day-to-day applications.

Nitrile O-Rings

Nitrile O-rings are a general type of O-rings. They offer a fairly respectable temperature range of -58 °F to 248 °F (-50 °C to 120 °C), with a high tensile strength that resists tears and damage.

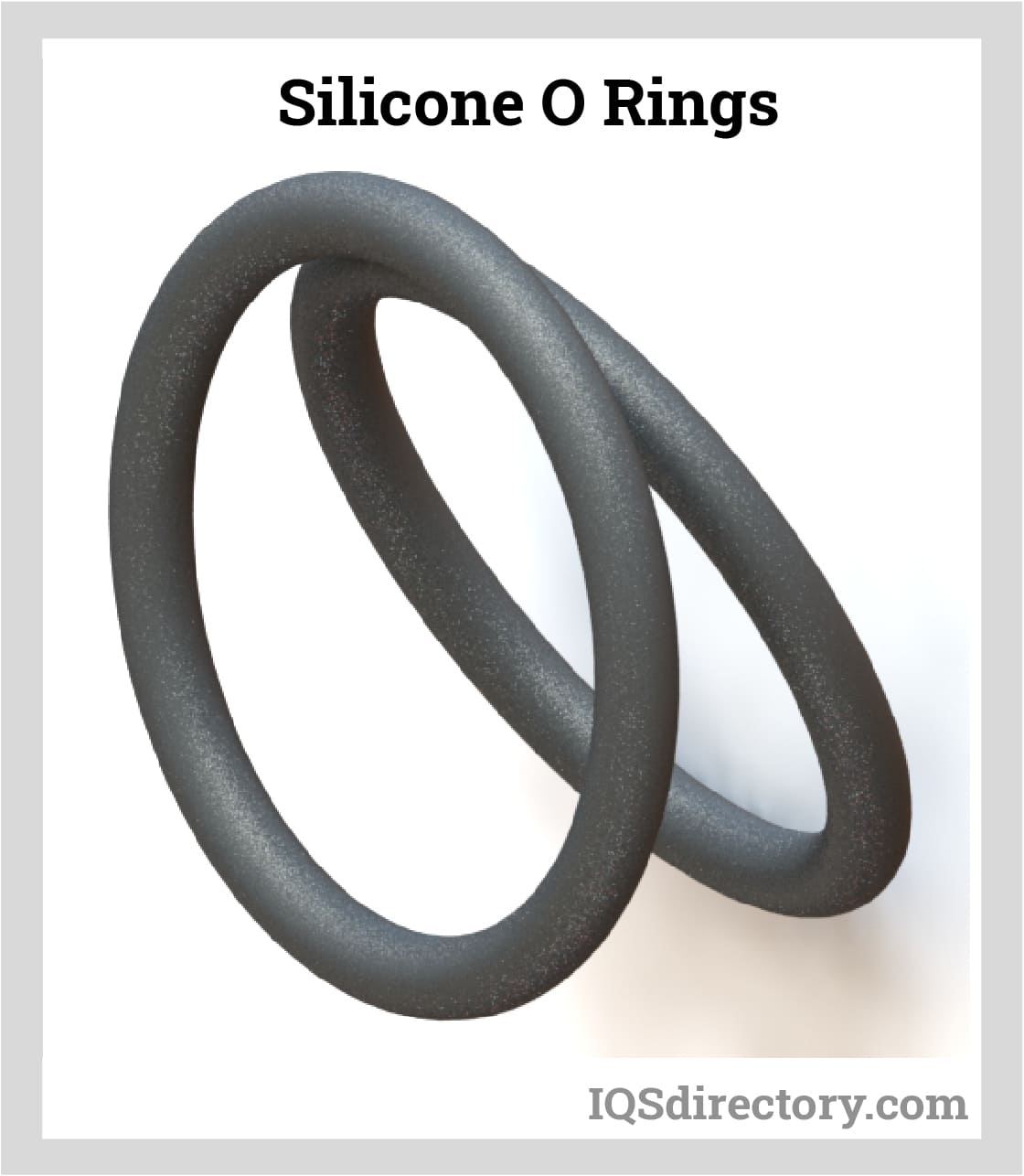

Silicone O-Rings

Silicone rings can withstand higher temperatures than nitrile rings, ranging from -148 °F to 572 °F (-100 °C to 300 °C). They offer greater flexibility and are ideally used in water and steam because of their toughness. However, this type is prone to tear and abrasion damage.

Viton O-Rings

Viton O-rings are also known as FKM O-rings and are manufactured from fluorocarbons. They have a greater resistance to temperatures ranging from -40 °F to 482 °F (-40 °C to 250 °C). These types of rings are ideal in acidic conditions and other fluids.

FEP O-Rings

These rings have a coating of fluorinated ethylene propylene and offer numerous advantages over standard rings. They are capable of handling temperatures as low as -76 °F and as high as 500 °F (-60 °C to 260 °C). They also offer greater elasticity and low friction capabilities.

PFA O-Rings

This O-ring encapsulates perfluoro alkoxy and is an attractive alternative to PEP and PTFE rings. It is ideal for petrochemical and acidic fluids. In addition, they can withstand temperatures higher than 482 °F (250 °C). Because of this, PFA rings are commonly used in the food sector and pharmaceutical organizations.

USP Class VI O-Rings

USP stands for United States Pharmacopeia. These USP rings have achieved a Class VI certification. They have been subjected to testing procedures to assess consistency, quality, and strength so that they are safe to use in scenarios where human life is at stake.

Vulcanized O-Rings

Vulcanized O-rings are made by treating a parent material with sulfur at elevated temperatures and splicing its ends to create a donut shape. This facilitates a reduced cost of production and large-scale production.

Large O-Rings

Large O-rings are made from the process of vulcanization; the process can be done with alterations to the ring diameter. Basic O-rings are made with a diameter of 1 inch (25.4 mm). Other variations can be made in the thickness of the material.

Applications of O-Rings

The automotive industry uses O-rings in passenger vehicles and aerospace products that undergo extreme conditions. The rings are also used when chemical exposure, rampant vibrations, and very high temperatures are common. In the medical field, the rings are used in syringes, pumps, filters, and connectors.

O-rings are also used in common applications where fluids are transmitted from one medium to another. Industrially, O-rings are used in valves, fittings, gas pumps, dispensers, and storage tanks that require sealing solutions. In the electronic industry, the O-rings are particularly used in semiconductor processing and to ensure dust protection in consumer electronics.

Benefits of O-Rings

O-rings have a wide range of benefits. They are suitable for various forms of sealing machinery, be they static or dynamic parts. The rings are also suitable for materials with standard dimensions and grooves for assured interchangeability. O-Rings are best at sealing media that transmit oils, gasses, and chemicals (acidic or alkaline). Finally, they have a simple design with a compact structure and a convenient assembly and disassembly mechanism.

Choosing the Correct O-Ring Seal Supplier

To ensure you have the most beneficial outcome when purchasing O-ring seals from an O-ring seal supplier, it is important to compare several companies using our directory of O-ring seal suppliers. Each O-ring seal supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each O-ring seal business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple O-ring seal companies with the same form.

Die Cutting

Die Cutting Foam Fab

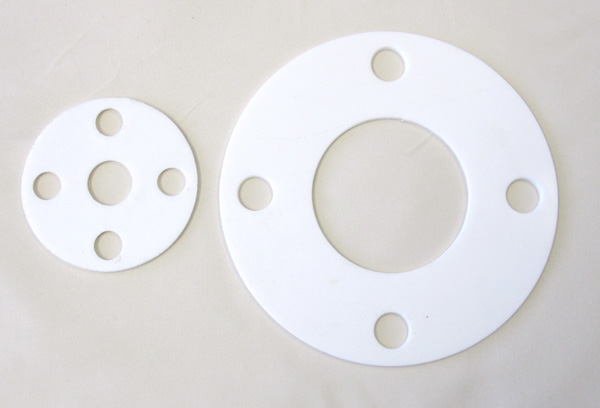

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services