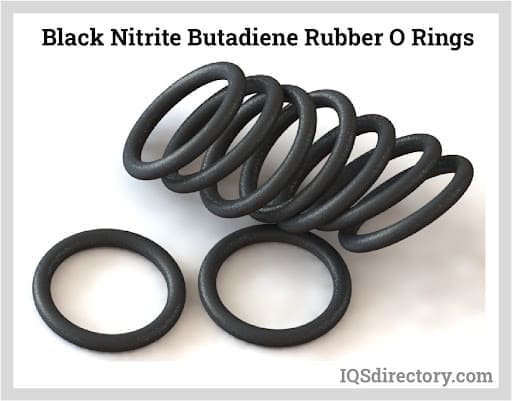

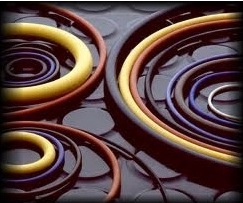

A rubber O-ring is a mechanical gasket manufactured in the shape of a donut or a torus. It is used for static and dynamic uses where there is potential friction and relative motion between parts. They are usually made from different types of rubber, such as nitrile, silicon, Viton, and other rare synthetic rubber materials. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Rubber O-Ring Manufacturers

How do Rubber O-Rings Work?

The O-ring is manufactured with other metallic hardware to fit the breadth of the assembly perfectly. The O-ring is fitted into the metal hardware's breadth and then compressed when the second piece is fitted into place. The compression ensures an airtight condition and facilitates full contact with the metal frame's inner and outer walls.

The natural resilience of the ring creates a perfect seal to stop any contents, liquid or gas, from slipping through the barrier. As the fluid exerts pressure on the O-ring, it is pushed against the wall on the low-pressure side, thereby increasing the seal's strength. When the pressure is released, the O-ring material will allow it to contract and return to its initial shape, thus maintaining the O-ring's seal and overall integrity.

Types of Rubber O-Rings

The different types of rubber O-rings include:

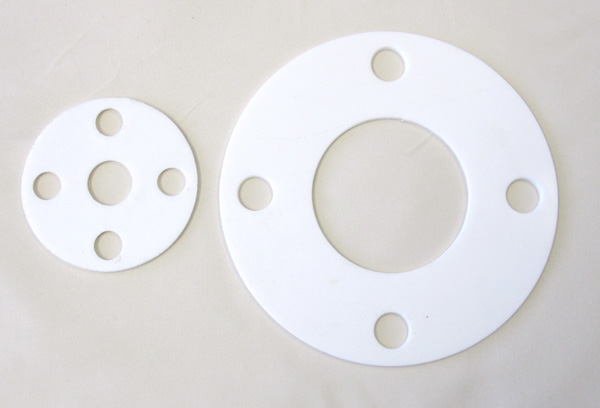

Square Rubber O-Rings

As the name states, square rubber O-rings have a square cross-section. Also known as lathe and washer cut rings, they are very flexible and used to make leak-proof connections. The square ring is seated in a groove, and as the two surfaces are pressed together, the ring conforms to the groove and forms a secure, permanent seal.

Hollow O-Rings

Hollow rubber rings have the same shape as regular O-rings and flow into a groove similarly when a force is applied. The difference is that hollow rubber rings easily compress and fill the grooves. Furthermore, they are unsuitable for dynamic and high-pressure applications, though they can still be used in standard and non-standard grooves.

Coated Rubber O-Rings

These rubber rings are coated to increase their resistance to friction, harsh weather conditions, chemicals, and abrasive actions. The coat also makes the rings non-sticky or bendy.

Back-Up O-Rings

Back-up O-rings are usually meant to protect the seal of an O-ring from extrusion when put under extreme conditions. They lessen the space where the O-ring would protrude from and add additional support to the structure so that high temperatures and pressures are withstood.

Encapsulated Rubber O-Rings

These rings have an inner core made of flexible rubber and covered with a layer that protects from corrosion and resistance to extreme conditions. The layer types usually include fluorinated ethylene propylene or perfluoro alkoxy-copolymer. These two polymers are used because they offer greater resistance to destructive chemicals and improved mechanical properties to resist stress and cracking. However, the encapsulated rubber rings are easily worn out by moving parts, limiting them to static applications where movement is minimal.

Applications of Rubber O-Rings

O-rings seals are used in high-pressure sealing jobs. O-ring rubbers are used in mechanisms where fluids are transmitted at very high pressures because they deform and fill up the grooves in the gasket, leaving little room for contents to sip out. High turbo engines also use rubber O-rings because of their resistance to very high temperatures and ability to retain hydro chemicals and solvent-based compounds. The plumbing industry also uses rubber O-rings as they provide waterproof sealing in water pipes.

Benefits of Rubber O-Rings

Rubber O-rings are widely used in multiple applications because they come in numerous sizes for varying pipe and joint sizes. They also come in varying hardness and textures to suit different applications. The rings also have a simple design, making them easy to use, and are self-seating as they do not require any tool adjustments. They are also cost-effective since they do not have complex requirements.

Choosing the Correct Rubber O-Ring Manufacturer

To ensure you have the most constructive outcome when purchasing rubber O-rings from a rubber O-ring manufacturer, it is important to compare several companies using our directory of rubber O-ring manufacturers. Each rubber O-ring manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber O-ring business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple rubber O-ring companies with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services