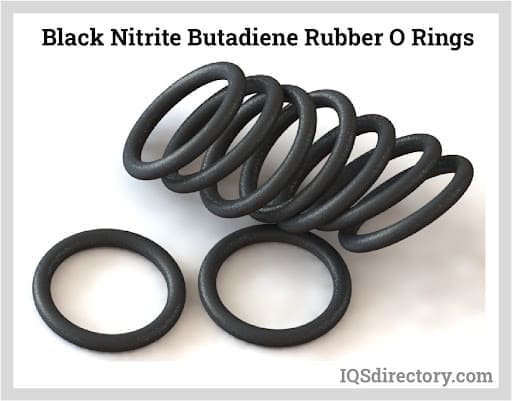

These O-rings are resistant to UV damage, corrosion, oils, chemicals and solvents. They are used for electrical insulation and are dielectrically stable. Silicone O-rings aren’t toxic, and therefore are FDA approved to be used in food handling equipment and appliances. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

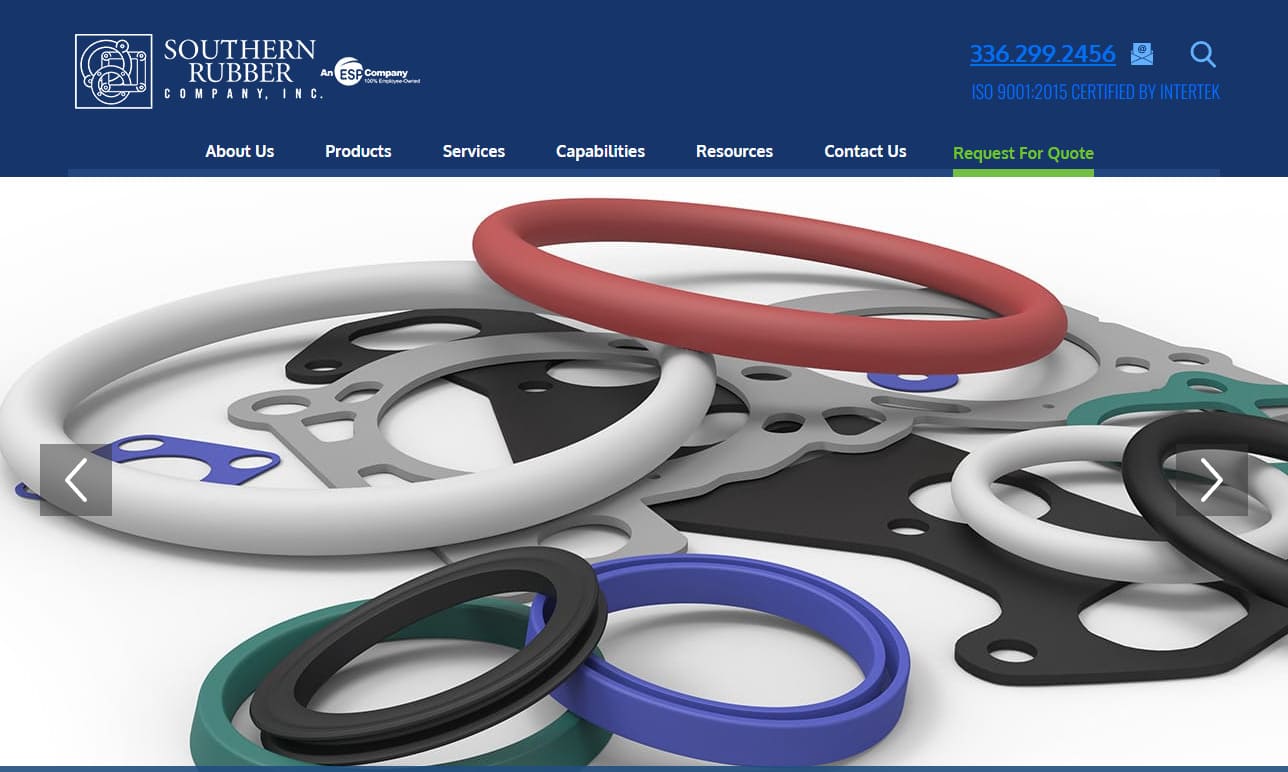

At Southern Rubber Company, Inc., we have built our reputation on providing high-quality O-rings that offer exceptional sealing performance in a wide array of applications. With years of industry experience, we understand the critical role that O-rings play in ensuring the reliability and safety of your systems.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

At Gasket & Seal Fabricators, Inc., we specialize in providing high-quality sealing solutions tailored to meet the diverse needs of our clients across various industries. Our extensive product line includes a wide range of O-rings, crafted from top-grade materials to ensure durability, reliability, and optimal performance. We understand that each application demands precision, and we pride...

At Bay Seal Company, we pride ourselves on being a leading provider of high-quality O-rings, delivering exceptional products and services tailored to meet our customers' diverse needs. Our extensive range of O-rings encompasses various materials, including rubber, silicone, and polyurethane, ensuring we have the perfect solution for every application.

More Silicone O-Ring Manufacturers

Silicone is an inert material, meaning it doesn't react with most chemicals. The medical industry therefore uses it for applications like complex medical implant systems that have moving parts requiring a sealant such as an o-ring. The aerospace, automotive, food processing and jewelry industries use silicone O-rings in their machinery and tubing or piping systems as well.

Silicone o-rings sometimes require the use of a lubricant, if the two pieces it is wedged between are moving pieces. The lubricant protects the silicone from quick deterioration. This is a common thing among all o-rings, whether they are metal or rubber, flat or round.

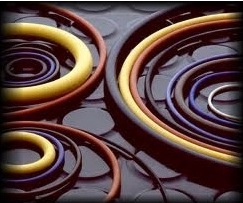

Silicone o-rings are naturally an opaque and partially transparent color, which is why they are sometimes called clear o-rings. However, clear o-rings are also produced from other materials such as Teflon, and silicone o-rings can be altered to match any color available.

Silicone is an element derived from quartz. For use as an o-ring, three other chemicals are added; methyl, phenyl and vinyl. The combination of these four elements make the silicone used for silicone o-rings a synthetic material. Its temperature resistance ranges from -60°C to 225°C, and some special varieties are able to range from -100° to 300°C.

They come in many different sizes, and are formed by joining a piece of silicone cord at its ends. Silicone itself is developed in two major fashions. Liquid silicone rubber, also known as LSR, must be heated and cured to reach its moldable state, while high consistency rubber (HCR) must be melted and then cooled before it can be set in a solid state.

LSR is the silicone best suited to o-ring designs. Silicone O-rings are odorless, non-toxic and will never grow mold. Although they are flexible in low temperatures, they have low tensile strength, poor tear strength and low wear resistance.

A Teflon sleeve is one possibility for additional protection from erosion since Teflon is stronger it works well as a cover for less durable o-ring materials. O-rings made of silicone are therefore better suited to perform in higher temperature applications.

Die Cutting

Die Cutting Foam Fab

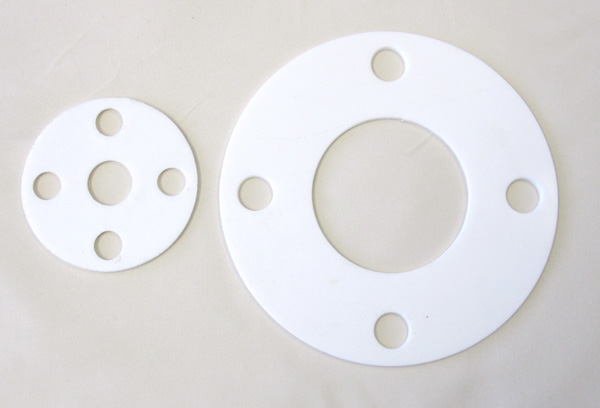

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services