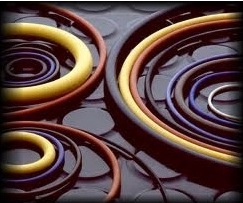

Teflon O-rings are comprised of a tough, stiff material that resists high temperatures and environmental elements. Teflon is a stiff material that won’t seal properly; thus, its mechanical qualities are worse than those of O-ring rubber. However, Teflon O-rings are ideal for a few particular applications, such as paint guns and automobile steering systems. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Teflon O-Ring Manufacturers

How Teflon O-Rings Are Manufactured

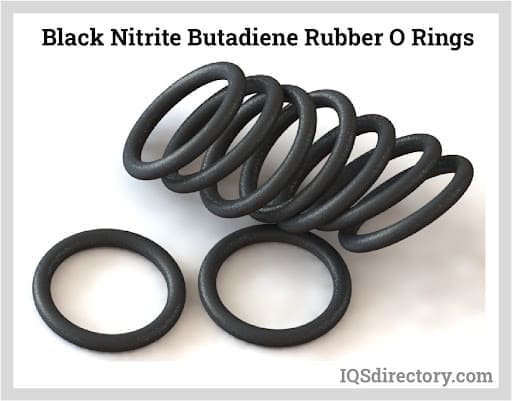

A variety of manufacturing processes, including extrusion, compression molding, injection molding, transfer molding, and machining, are used to make O-rings. They can be made from a wide range of materials, including silicone, polyurethane, neoprene, nitrile rubber, fluorocarbon, and other elastomers, depending on the application. Teflon O-rings are made from a polymer with a high molecular weight called polytetrafluoroethylene (PTFE) using the different methods below:

O-Ring Extrusion

Many O-rings are produced by extrusion. During the extrusion manufacturing process, a raw material is forced through a die or a set of dies, adopting the die's shape as it passes through. Some extrusion methods also call for a hopper to pour the heated raw material. O-rings are produced using a ring-shaped die. Extrusion comes in a variety of forms, such as cold, friction, and micro extrusion.

Pressure Molding

Pressure molding is another industrial technique used to make Teflon O-rings. It also goes by the name of compression molding and uses pressure and heat to produce three-dimensional objects. Some manufacturing businesses pump heated PTFE into a mold cavity to form Teflon O-rings. The top of the mold cavity is then equipped with a stopper that can apply pressure to the mold cavity. As pressure builds up inside the mold cavity, the preheated material takes the shape of the mold cavity.

Injection Molding

Teflon O-rings are also produced using the manufacturing method known as injection molding. Raw material (PTFE) is injected into a mold cavity in this process. The substance is heated to liquify it, and then it is injected into a mold cavity.

Transfer Molding

Pressure molding and transfer molding are comparable. In both production methods, a mold cavity is filled with preheated material. Compression molding and transfer molding both require mold cavities, but compression molding needs an open mold cavity. Transfer molding's closed mold cavity allows for the creation of higher pressure. As a result, finished items like O-rings frequently have a thicker and more uniform pattern.

Considerations When Using Teflon O-Rings

Compared to other materials, Teflon plastic O-rings are considered fairly restricted because they can only be utilized in temperatures between -100 and 400 °F (-73 to 204 °C). Teflon O-rings cannot be melted; thus, compression and sintering are used to create its rounded shape. Other O-ring polymers are formed using heat or die cutting equipment after a curing procedure. Many elastomeric O-rings have a Teflon sleeve or covering that shields the least durable rubber material from abrasion as well as from damaging and corrosive substances.

Teflon is ideal for preventing surface wear because it has a very low coefficient of friction and is inert, or chemically reacts with essentially no substances. Lubrication is another method for preventing O-rings from deterioration, especially when they are sealing two moving elements. Teflon is also non-permeable, uniform, nonflammable, able to withstand strong impact, and doesn't swell in response to temperature changes.

Characteristics of Teflon Rings

Since Teflon is one of the slipperiest solids ever created, it is resistant to almost all industrial chemicals and solvents, withstands extremely high temperatures, and is a superb insulator. Because of these properties, O-rings made from this material are frequently used for items that need an anti-stick surface. Teflon’s low coefficient of friction makes it an excellent choice for situations where components would move against one another.

Applications of Teflon O-Rings

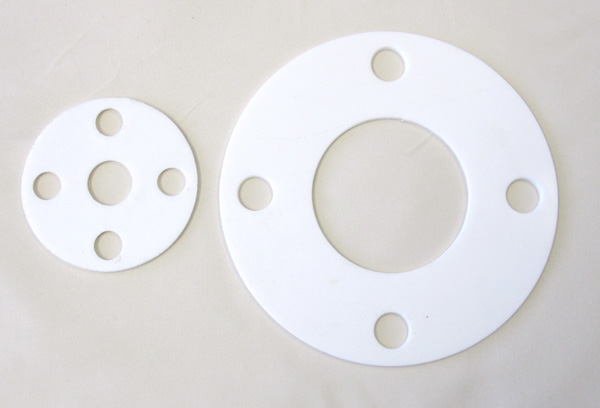

Teflon O-rings occasionally incorporate additives, including glass, charcoal, graphite, and bronze, to increase the material's mechanical strength, stability, and wear resistance. Since many metal O-rings also incorporate plastic components to fill out their shapes, the practice of using metal as a filler for rubber Teflon O-rings is the same process in reverse. This procedure guarantees that O-rings will effectively seal the gap between two components of a machine or pipe system.

Teflon O-rings are useful in various applications in the automotive, medical, pharmaceutical, electrical appliance, and aerospace industries, particularly when additives are utilized. Brake systems, hydraulic cylinders, pistons, heat exchangers, and various water pumps are a few specific examples.

Benefits of Teflon O-Rings

- Compact installation space, simple structure, and small footprint

- Routine adjustment is not necessary because of their self-sealing function

- Static-sealing applications with good sealing performance and no leaks

- The movement has a low friction resistance, making it ideal when the strain changes

- Lightweight, affordable, and reusable

- Flexible for use in a wide range of implementations

Drawbacks of Teflon O-Rings

- Teflon O-rings are more complex than other O-rings

- Need special finishing after installation to regulate and reduce the higher leakage rate

- Cannot be reinstalled or reused

- Becomes disposable after a single use, unlike rubber seals

Because of all these factors, Teflon O-rings are only chosen when stronger chemical resistance and extreme temperature ranges are needed. Otherwise, rubber compound O-rings are typically favored over Teflon.

Choosing the Correct Teflon™ O-Ring Supplier

To ensure you have the most positive outcome when purchasing Teflon O-rings from a Teflon O-ring supplier, it is important to compare several companies using our directory of Teflon O-ring suppliers. Each Teflon O-ring supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review eachTeflon O-ring business using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple Teflon O-ring suppliers with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services