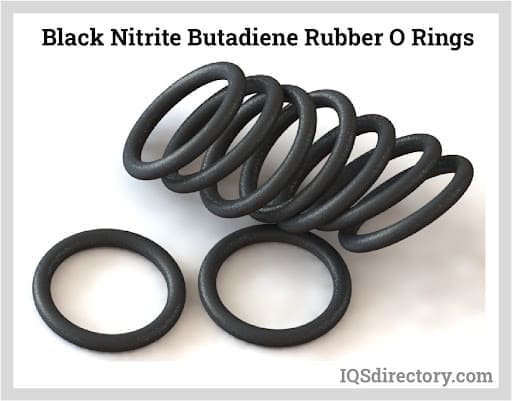

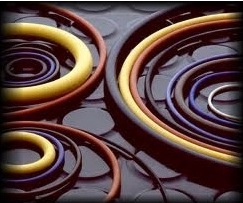

Viton O-rings are made from a material called Viton, a registered trademark of DuPont. It can also be referred to as FKM. These are mechanical gaskets with a donut shape, made from fluoropolymer elastomer and synthetic rubber. In addition, Viton O-rings are highly resistant to fuels, chemicals, and high temperatures. Read More…

Since 1989, we have been an o-ring distributor. We offer commercial, FDA, military, metric o-rings, caps, plugs, gaskets & more. Custom, rubber o-rings, metal o-rings, diaphragms, face seals and non-standard o-rings are also offered.

At Global O-Ring and Seal, LLC, we are dedicated to quality assurance, continually investing in rigorous product testing and validation processes to guarantee the reliability and performance our customers expect. Our goal is simple yet vital—to ensure that each sealing solution we provide is precision-engineered, durable, and perfectly suited to the demands of your applications.

RD Rubber Technology Corp is an ISO 9001:2015 / AS9100:2016 certified and ITAR registered company. We offer compression, transfer, injection and Liquid Injection molding, rubber to metal bonding, engineering support, tooling design, machining and more. Our customers rely on us to give them the best possible production o-rings. From aerospace to medical, food processing to military applications we ...

We manufacture custom o-rings at no tooling charge and no minimum order requirement. Since 1983, we have lead in sealing products with a complete range of o-ring seals, oil seals, o-ring kits, o-ring cord, hollow o-rings and metal bonded o-ring products. ISO 9002 certified with 24-hour service.

At Wyatt Seal, we specialize in delivering reliable sealing solutions, with a strong focus on high-performance O-rings. We pride ourselves on being more than just a distributor—we're problem solvers, collaborators, and partners to a wide range of industries that depend on consistent, leak-proof performance. Our selection of O-rings includes a vast array of materials, sizes, and profiles to suit ...

At American Rubber Corporation, we take pride in delivering precision-engineered rubber products that meet the highest standards of quality and performance. Our expertise in manufacturing O-rings has established us as a trusted partner across industries where durability, accuracy, and reliability are critical.

More Viton O-Ring Manufacturers

Viton O-rings are used in static and dynamic applications involving relative motion between parts.They are used in applications that have the possibility of friction. Viton O-rings exhibit chemical resistance and are the most suitable for use in pumps used for agricultural, disinfection, pest control, lawn care sprayers, and mold remediation. This is due to the resistance to hydrocarbons in some of the compounds. These applications are more suited to Viton O-rings because they can withstand sun exposure and other environmental conditions.

Characteristics of Viton O-rings

Viton O-rings exhibit the following characteristics:

- Excellent acid resistance

- Fair electrical properties

- Good abrasion resistance

- Fair cold resistance

- Fair water and steam resistance

- Fair-to-good tear resistance

- Good impermeability

- Good chemical resistance

- Excellent flame resistance

- Excellent heat resistance

- Good-to-excellent tensile strength

- Good-to-excellent set resistance

- Good-to-excellent dynamic resistance

- Excellent weather resistance

- Excellent ozone resistance

- Excellent oil resistance

Types of Viton O-rings

The various types of viton O-rings include:

Type A Viton O-Rings

These types of Viton O-rings are made from di-polymers of VF2/HFP. They are general-purpose O-rings utilized in the automotive and aerospace industry. Type A Viton O-rings have a composition including 66% fluorine content.

Type B Viton O-Rings

These types of Viton O-rings are made from terpolymers of VF2/HFP/TFE. They are most suitable for use in chemical processing plants as well as power/utility applications. They have a composition that includes 68% fluorine content.

Type F Viton O-Rings

Type F Viton O-rings are highly resistant to concentrated aqueous inorganic acids, steam, water, and oxygenated automotive fuels. These types of Viton O-rings contain a fluorine content of 70%.

Specialized Type Viton O-Rings

These specialized O-rings are copolymers of TFE/propylene and ethylene/TFE/PMVE. They are the most suitable for application in the automotive industry and also for oil exploration, ultra-harsh environments, and sealing requirements.

Applications of Viton O-Rings

Viton O-rings are utilized in very harsh environments where chemical interactions and temperature extremes are common. They are utilized in appliance processing, chemical, and automotive industries. Their use is not only limited to those areas of application but goes further to transportation businesses, petroleum refining, aerospace companies, and oil and gas exploration industries.

Benefits of Viton O-Rings

The benefits of Viton O-rings in industries include:

- They are the most hard-wearing O-rings.

- They are high-performance O-rings due to the Viton material and are also very durable, making them the top choice for many different applications.

- Viton O-rings are incredibly versatile for difficult applications

- Viton O-rings exhibit high operating temperature ranges and better resistance to degradation when exposed to weather and ozone.

- They are more chemically resistant and are capable of withstanding a range of chemicals like oils, silicone fluids and gasses, acids, and aromatic and halogenated hydrocarbons.

- These O-rings are long-lasting, meaning they enjoy extended intervals between services. This, in turn, reduces the costs of maintenance and provides more reliable seals.

- Viton O-rings overcome most environmental challenges. They can maintain seals even in the presence of UV exposure, ozone, weather, fungus, oxidation, or mold.

Disadvantages of Viton O-Rings

The disadvantages of viton O-rings include:

Incompatibility

Viton O-rings are incompatible with ketones, including methyl ethyl ketone, acetone, ester solvents like ethyl acetate, organic acids like acetic acid, and amines.

Performance

Viton O-rings are not ideal for every application. For example, under excessively high temperatures, Fluoroelastomers can decompose and release hydrogen fluoride, which is toxic. It is also associated with ongoing irritation of the respiratory tract. At extremely low temperatures, Viton O-rings harden and become inflexible.

Choosing the Correct Viton™ O-Ring Supplier

To ensure you have the most productive outcome when purchasing Viton O-rings from a Viton O-ring supplier, it is important to compare several companies using our directory of Viton O-ring suppliers. Each Viton O-ring supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each Viton O-ring business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple Viton O-ring companies with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services